Product Class

+ High efficiency grinding+ Choose powder equipment+ Dust removal equipment+ Grinding equipment+ Sand production equipment+ Drying equipment+ Wear-resistant overlaying welding+ Desulfurization denitration

Contact Person:Mr Zhu

Mob:13851188001

Web:www.******.top

Choose powder equipment

Your current location:Home>>Product>>Choose powder equipment

- Combined raw material separato

- Classification:Choose powder equipment Clicks:43 Release date:2019-03-11

An overview,

In the cement industry, in order to improve the efficiency of the grinding system and reduce the energy consumption, the circulating grinding system is widely used. As an important part of the system, the performance of the classifier has a direct impact on the efficiency of the system. Therefore, the research and development of powder separator has been paid attention to by scientific research institutes and industrial and mining enterprises.

JD series high efficiency anti-condensation combined form of double-rotor separator is the latest type of powder separator developed and developed by technicians of yancheng jida machinery manufacturing co., LTD. Combining with advanced powder separation technology from abroad, the theory of plane eddy current is well applied to the cyclone type separator. It has been proved that the efficiency of powder selection reaches 85-90%, the fineness adjustment is convenient and flexible, and the performance is stable and reliable.

Ii. Working principle

The system structure of JD series high-efficiency anti-condensation combined double-rotor separator is shown in figure 1. Its working principle is as follows:

1, the final by the classifier upper hopper into the classifier inner shell, fall into an organic whole with rotor of screw and material plate, in materials plate under the action of high-speed rotating around out, at the same time by the effects of the rising air propeller blade and materials plate lifted upward, in materials plate material is formed on the propeller blade. The finer particles in the material float upward and are suspended and dispersed, while the coarser or heavier materials are dispersed and fall down along the wall of the cylinder by the spatula blade to complete the first powder selection.

2. The upper cage type rotor 10 is set below the distributor plate. The lower cage type rotor rotates together with the spindle to form eddy current, which will disperse the heavy and heavy materials falling along the cylinder wall again.

3. Cage rotor 6 is set above the distributor plate. In the powder selecting room, the airflow near the surface of the classifying ring of the upper cage rotor and the materials dispersed in the air flow are driven by the classifying ring to rotate with the classifying ring at a high speed, and the classifying ring moves with high speed together to form a uniform and strong vortex airflow around the classifying ring. In this region, the relationship between centrifugal force and suction force at any position is constant. The centrifugal force of materials in the air flow can be adjusted by adjusting the speed of motor 2 and spindle 3. When the rotating speed increases, the force also increases. At this time, if the air volume is kept constant, the cutting particle size decreases and the product becomes fine. If the speed is reduced, the product becomes coarse.

4. After classifying by the upper cage rotor, fine particles enter into the external cyclone dust collector with the circulating wind. Due to the newly designed cyclone dust collector, a guide plate is added to the air inlet, a reflection screen is added to the inner cone, and a deceleration plate is added to the lower end, so that the fluid resistance of cyclone dust collector is greatly reduced. Under the action of the wind guide plate, the circulating wind enters the cyclone collector with high wind speed. The velocity of the expanded part of the snail Angle decreased suddenly, accelerated the particle deposition, and improved the dust collecting efficiency of the cyclone dust collector.

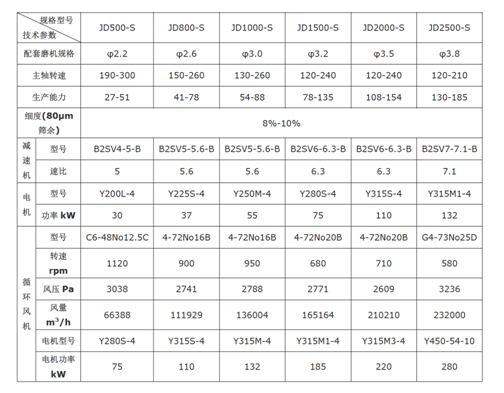

Technical parameters table

-

Last:Special sand cl

Next:Coal mill dynam