Product Class

+ High efficiency grinding+ Choose powder equipment+ Dust removal equipment+ Grinding equipment+ Sand production equipment+ Drying equipment+ Wear-resistant overlaying welding+ Desulfurization denitration

Contact Person:Mr Zhu

Mob:13851188001

Web:www.******.top

Desulfurization denitration

Your current location:Home>>Product>>Desulfurization denitration

- Semi-dry desulfurization

- Classification:Desulfurization denitration Clicks:17 Release date:2019-03-11

An overview,

Circulating fluidized bed flue gas desulfurization process is the end of the eighty s Germany LURGI (pidec in) the development of a new semi dry process desulphurization technology, the technology based on the principle of circulating fluidized bed to dry hydrated lime powder Ca (OH) 2 as absorbent, through many times of the absorbent recycle, the extension of the absorber with the flue gas desulfurization tower, contact time, in order to achieve the purpose of efficient desulfurization, greatly improving the utilization of the absorbent at the same time. Acid gases such as SO2, SO3, HF and HCL in flue gas can be effectively removed by chemical reaction. Desulphurization end product desulphurization slag is a free-flowing dry powder mixture without secondary pollution and can be further utilized comprehensively. This process is mainly applied to the flue gas desulfurization of power station boilers. The amount of flue gas treated by a single tower can be applied to boilers with a evaporation capacity of 75t/h ~ 1025t/h, and the SO2 removal rate can reach 90% ~ 98%.

Ii. Process principle of CFB semi-dry desulfurization system

Ca (OH) 2+ SO2= CaSO3 + H2O

Ca (OH) 2+ 2HF= CaF2 +2H2O

Ca (OH) 2+ SO3= CaSO4 + H2O

Ca (OH) 2+ 2HCl= CaCl2 + 2H2O

CaSO3 + 1/2 o2 = CaSO4

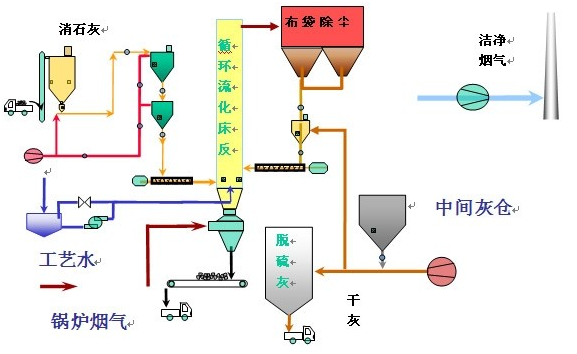

Iii. Flow chart

Iv. Composition of CFB semi-dry desulfurization process system

1. Desulfurizer preparation system

2. Desulfurization tower system

3. Dust collector system

4. Process water system

5. Flue gas system

6. Desulfurization ash recycling system

7. Desulfurization ash exhaust system

8. Electronic control system

Technical characteristics of CFB semi-dry desulfurization process

1. The flue gas and desulfurizer in the desulfurizer tower have sufficient reaction, long residence time and high cycle utilization rate of desulfurizer;

2. There are no rotating parts and wearing parts in the desulfurization tower, and the whole device is maintenance-free;

3. The desulfurizer and desulfurizer slag are both dry, and the system equipment will not produce adhesion, blockage, corrosion and other phenomena;

4. The desulfurization efficiency can be satisfied only by adding desulfurizer without adding any equipment when the type of coal is changed;

5. High SO2 removal rate is guaranteed, low dew point of flue gas after desulfurization, and no anti-corrosion measures are required for equipment and flue pipe;

6. The desulfurization system can adapt to a wide range of boiler load, up to 30% ~ 110% of the boiler load;

7. Simple desulfurization system, small plant area;

8. The desulfurization system has low energy consumption and no waste water discharge;

Low cost of investment, operation and maintenance.

-

Last:Dry desulfuriza

Next: 一篇